Gacia Completes Smart IoT Circuit Breaker Integration for Production Line Equipment Management

Release time:

2024-08-26

As Gacia continues to deepen its efforts in upgrading and transforming automation and digitalization, we remain committed to investing in advanced manufacturing. Recently, we successfully deployed and integrated smart IoT circuit breakers across over 700 production line devices. This integration aims to collect energy consumption data from production line equipment, ensuring stable operation of the production lines by leveraging next-generation information technology.

Gacia has consistently adhered to its core value of "customer and market-oriented productism," by achieving a comprehensive intelligent upgrade of equipment management. This ensures high-efficiency production, high-quality products, and stable delivery times for our customers. Gacia’s intelligent equipment management module includes centralized control, equipment repair, and smart IoT functionalities.

Remote Monitoring and Centralized Management

Currently, our multi-floor factory hosts over 700 diverse devices spread across different workshops. Through centralized management of repair requests, the entire factory can manage hundreds of maintenance orders with just a team of three, streamlining the repair process significantly.

Smart Repairs and Rapid Response

When equipment encounters anomalies during operation, the system immediately triggers an alert, and maintenance personnel receive repair notifications directly on their mobile devices. Additionally, by setting pre-warning conditions, the system can intelligently plan maintenance schedules, ensuring every piece of equipment is serviced on time.

Smart IoT Integration

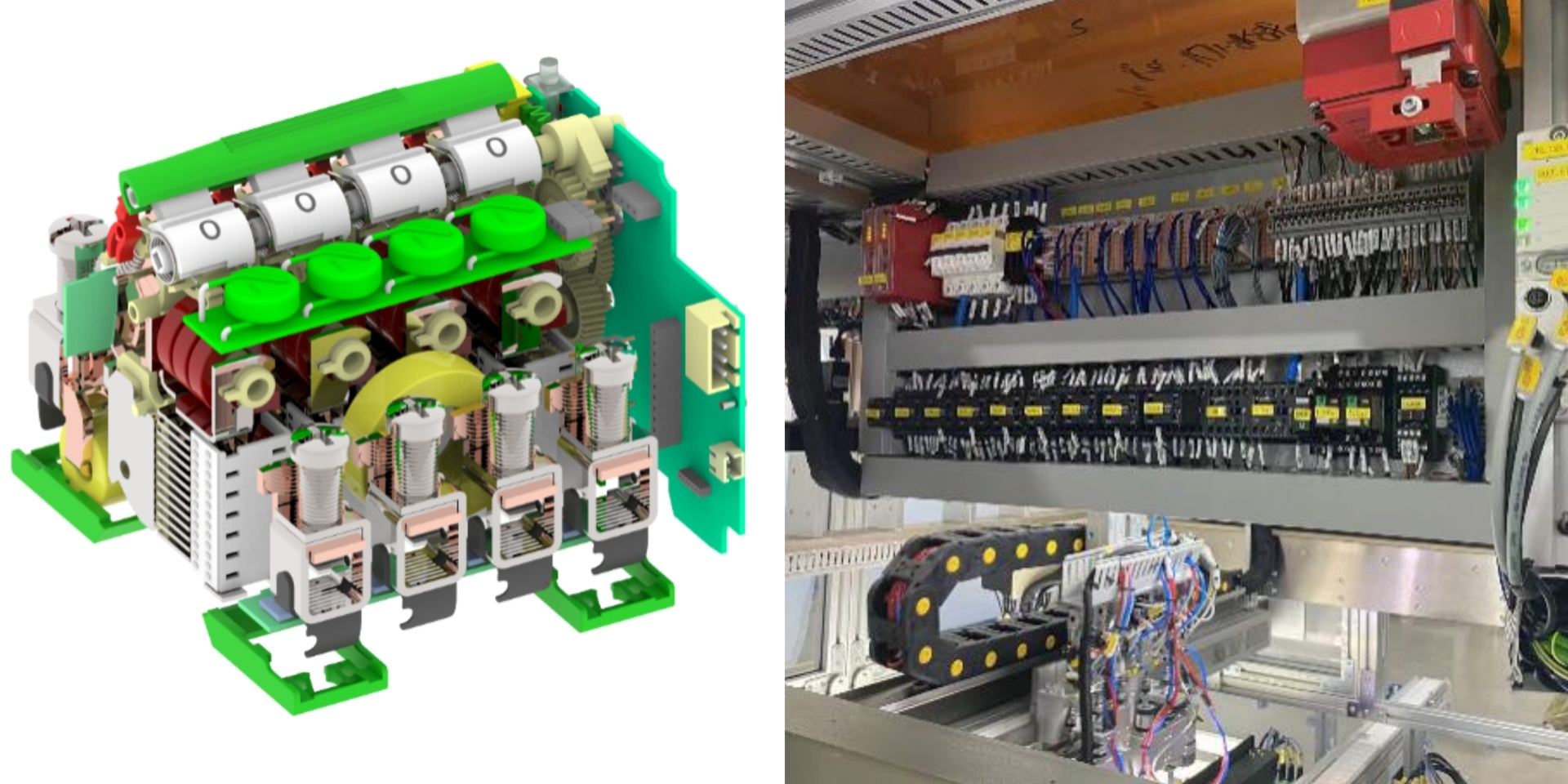

Using IoT smart circuit breakers, we achieve real-time monitoring and data collection of equipment energy consumption and status, which are then integrated into the intelligent equipment management module.

Quality Process Control

Beyond monitoring equipment energy consumption, the system also integrates machine status data, enabling comprehensive data collection on production conditions. This allows for quality process analysis, ensuring that the delivered products meet high-quality standards.

Digital Visualization of Production Line

By integrating IoT circuit breakers and equipment status data, we can aggregate, compare, and analyze multi-dimensional data such as energy consumption, production, and quality. This supports our continued efforts in intelligent and digital upgrades.

Training for Effective Implementation

To ensure the effective utilization of this module, the IT department organized comprehensive training sessions for employees, covering the use of the smart equipment management module. This not only improved the company's equipment management efficiency and economic benefits but also laid a solid foundation for the company's sustainable development. In the future, Gacia will continue to focus on technological innovation and product development, introducing more intelligent and efficient management solutions.